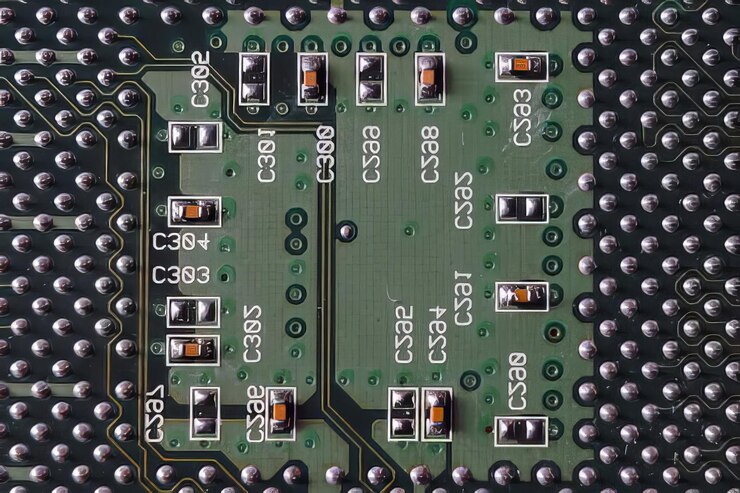

PCB prototyping plays a crucial role in the development and manufacturing of electronic devices, serving as the initial stage in bringing innovative ideas to life. However, the process is not without its pitfalls, and avoiding common mistakes is paramount to achieving successful outcomes. In this article, we will explore the nuances of PCB prototyping and highlight the significance of quality control measures. Additionally, we will delve into the best practices that can streamline the prototyping process and showcase the expertise of PCB-Togo Electronic, Inc. as a trusted partner in the realm of electronic manufacturing.

Introduction to PCB Prototyping

The Basics of PCB Prototyping

PCB prototyping is like the DIY crafting of the electronics world – but instead of glitter and glue, you’re dealing with copper and circuits. It’s where your design dreams get turned into functional reality on a tiny, flat board.

Overview of PCB-Togo Electronic, Inc.

Think of PCB-Togo Electronic, Inc. as the fairy godmother of PCB prototyping – they make your wishes come true without the pumpkin carriage. With a knack for turning schematics into tangible boards, they’re your go-to for electronic enchantment.

Common Mistakes in PCB Prototyping

Design Errors to Avoid

Forgetting to double-check your schematic is like baking a cake without flour – it just won’t work. Avoid the headache of misplaced components and unruly connections by thoroughly reviewing your design before sending it off.

Material Selection Pitfalls

Choosing the wrong materials for your PCB is like trying to fit a square peg in a round hole – it’s not going to end well. Make sure you pick materials that match your design requirements to avoid performance hiccups down the line.

Manufacturing Process Mistakes

Skipping steps in the manufacturing process is like skipping leg day at the gym – you’ll regret it later. From soldering mishaps to poor quality control, ensure each stage is given the attention it deserves for a smooth prototyping journey.

Importance of Quality Control in PCB Prototyping

Ensuring Functional Integrity

Quality control in PCB prototyping is like taste-testing a dish before serving it – you want to catch any off flavors before it reaches the table. Ensuring each component functions as intended is crucial for a successful end product.

Reliability Testing and Standards

Just like a good pair of shoes, your PCB needs to be reliable and up to standard. Testing its durability and adherence to industry regulations ensures that your creation can withstand the electronic marathon ahead.

Best Practices for Successful PCB Prototyping

Effective Communication with PCB Manufacturer

Communication with your PCB manufacturer is key – it’s like a successful relationship, but with less drama. Keep the lines open, convey your requirements clearly, and watch your prototype dreams come to life seamlessly.

Prototype Testing and Iteration

Prototyping isn’t a one-and-done deal – it’s a process of trial and error, like finding the perfect emoji for your text. Test, tweak, and iterate until your PCB prototype is as flawless as a cat meme – then pat yourself on the back for a job well done.

Utilizing PCB Prototyping Services from PCB-Togo Electronic, Inc.

Range of Services Offered

When it comes to PCB prototyping, PCB-Togo Electronic, Inc. offers a comprehensive range of services tailored to meet various project requirements. From quick-turn prototypes to high-volume production, their services include layout design, assembly, testing, and more.

Advantages of Partnering with PCB-Togo Electronic, Inc.

Partnering with PCB-Togo Electronic, Inc. for your PCB prototyping needs comes with a host of advantages. Their team of experienced professionals ensures accurate and efficient prototyping, quick turnaround times, competitive pricing, and exceptional customer service. Trusting your project with PCB-Togo Electronic, Inc. guarantees quality results every time.

Future Trends in PCB Prototyping Industry

Advanced Technologies in PCB Prototyping

The PCB prototyping industry is evolving rapidly, driven by advancements in technology. From miniaturization and flexible electronics to advanced manufacturing processes like additive manufacturing, the future of PCB prototyping holds exciting possibilities. Stay informed about the latest technological trends shaping the industry landscape.

Sustainability and Green Practices in PCB Manufacturing

As environmental consciousness grows, sustainable practices in PCB manufacturing are gaining prominence. PCB-Togo Electronic, Inc. is at the forefront of promoting green initiatives, such as recycling programs, eco-friendly materials, and energy-efficient production processes. Discover how sustainability is shaping the future of PCB prototyping and manufacturing practices.

In conclusion, navigating the landscape of PCB prototyping requires diligence, adherence to best practices, and a commitment to quality. By understanding and avoiding common mistakes, embracing innovation, and leveraging the expertise of reputable partners like PCB-Togo Electronic, Inc., manufacturers can enhance the efficiency and effectiveness of their prototyping endeavors. As the industry continues to evolve, staying informed about emerging trends and technologies will be key to driving advancements in electronic manufacturing.