In fast-paced e-commerce and logistics, the strength and durability of packaging boxes are paramount to ensure the safe delivery of products. A packaging container like a corrugated box should be strong enough to tolerate dropping, impact loads, mishandling, light collision, etc while in transit.

Box compression testing machine do a great job of ensuring the integrity of these car boxes and maintaining product security. This is a paper and packaging testing equipment that simulates the real-life scenarios of card box dropping and mishandling. A certain amount of compression load is employed on the packaging boxes to check their strength.

What is a Box Compression Testing Machine?

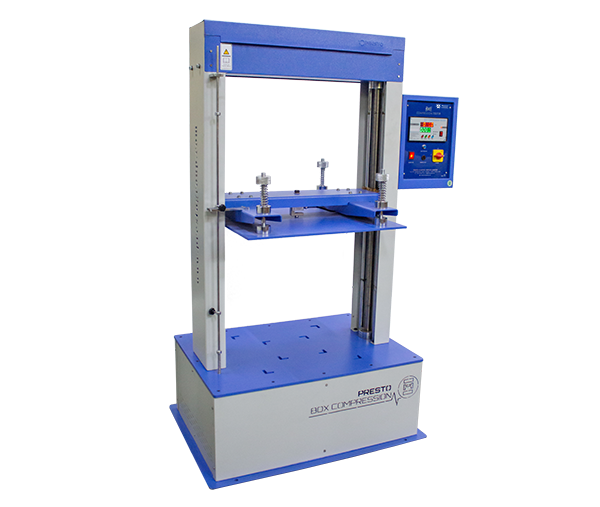

A box compression tester is a packaging testing lab equipment in which the compression strength of sample packaging boxes is tested. It has a flat metal plate that applies pressure and compressive force to the card box until it breaks down.

By measuring this compressive force, manufacturers ensure that these boxes can sustain a certain pressure during storage and transportation. Box compression testing machine is frequently utilized in packaging industries for the safe delivery of products in every circumstance.

How it Works

The working principle of the PackingTest box compressing machine is very simple in which a compression load is exerted on the sample box. Usually, the equipment is made up of a base stage and a moveable plate that presses down on the box’s top.

The pressure is raised gradually until a certain level is achieved or the container breaks. The device monitors the amount of pressure used and quantifies it, giving important information on the compression strength of the container.

An operator can easily adjust the height and the pressure of the plate that will be exerted on the packaging box. If required, manufacturers may improve the strength and the quality of corrugated boxes or other packaging boxes, as per company policies.

Why Box Compression Testing Machine is Important?

Box compression tester is an important paper and packaging testing equipment for various industries. The primary advantages of this equipment include excellent strength of packaging boxes, quality control, cost savings, optimized design, and most importantly it tells the company’s brand value.

Quality Control

With optimum quality, manufacturers can ensure that they deliver the best product to their customers. When boxes are sturdy and durable, they can meet the required standards for a particular product and industry. Additionally, quality products also prevent companies from product damage, customer complaints, and financial losses.

Cost Savings

It is always wise and cost-effective to test any product or material before it is launched for the market. Robust and pressure-resistant packaging boxes use less material, which ultimately reduces manufacturing expenses. Furthermore, sturdy packaging lowers the possibility of damage during shipment and transportation, which lowers the expense of replacement.

Optimizing Design

When compression testing is done, manufacturers come across various designs that can withstand maximum pressure and compressive force. You can test different materials for the same packaging box by altering its thickness and design. The more you test and fine your design, the stronger will your design be.

Meeting Industry Standards

Every industry has its own set of regulations and guidelines that must be met for every product. By testing, you can make sure your packing conforms with these standards and prevent shipment delays or cancellations. The compression testing machine ensures that packaging boxes are strong enough to meet the industry’s set standards.

Important Components of Box Compression Testing Machine

Box compression tester is a vital tool for the packaging industry to guarantee the strength and integrity of product delivery. Here are the key components that make up a box compression testing machine:

· Loading Frame – It is a rigid structure that houses all the elements for testing and provides stability to the machine.

· Drive System – Drives are motorized equipment that exerts compressive force on the sample. It can be electromechanical, pneumatic, and fully automatic to slide the plate up and down as per the required force.

· Solid Plate – The solid flat plate is a movable part and a crucial element of the whole machine that actually exerts pressure on the card box or packaging sample.

· Load Cell – An electrical signal that is transmitted to the control module to be interpreted is produced by the load cell from pressure.

· Control Unit – This is the brain of the whole machine that controls the speed of the drive system, monitors the load cell output, and displays the test results that can be further analyzed by experts.

Conclusion

Apart from producing quality products, it is also important that produced products reach the customer in the right condition. Paper and packaging testing equipment are vital tools for industries to safeguard their products. With measurement of the compressive strength of packaging boxes, manufacturers ensure that shipped products will not be damaged during transportation.